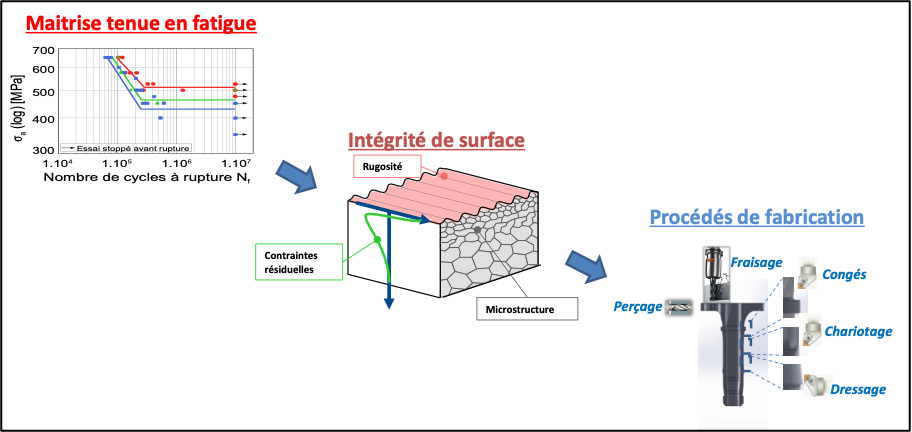

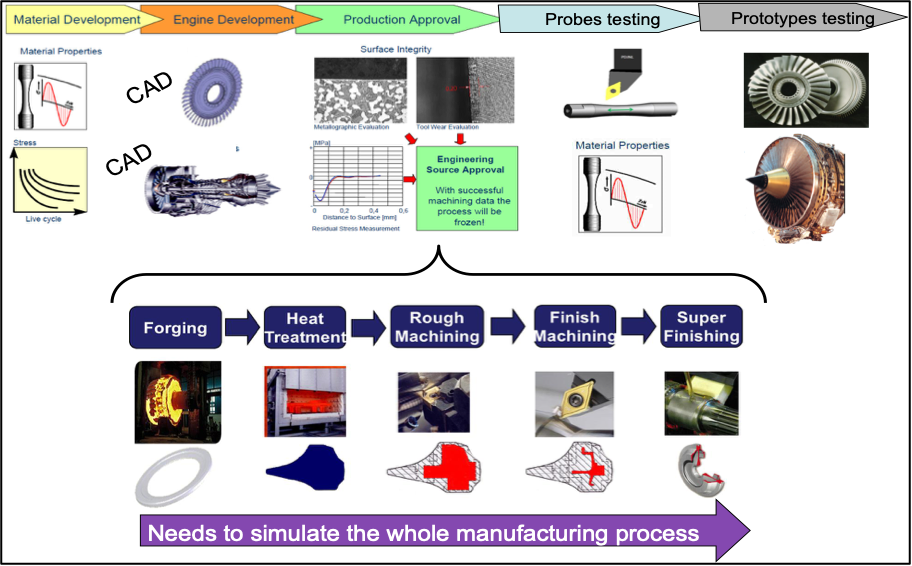

This translates into mastering the fatigue life of components and understanding the effect of complex processes on surface integrity.

.

Machining process

This notion of surface integrity generally takes into account in the literature the microstructural state of the metal, the level of residual stress and roughness. During the production of a part's surface, these three quantities are imposed by the machining process and, in particular, the finishing operation.

Computational prediction

Work undertaken over the last ten years or so on numerical process simulation has made it possible to envisage a computer prediction of surface integrity capable of speeding up product development processes while gaining a finer understanding of the phenomena brought into play.

To carry out this work, the set of tasks to be carried out were divided into three workpackages:

- Explore new manufacturing processes not addressed by existing work

- Integrate the industrial environment associated with processes such as tool wear or lubrication

- Program a commercial software solution

.